Source: Link Testing Instruments Co., Ltd

Toothpaste is one daily necessity in people’s life. Now there is a variety of toothpaste on the market and most of those products are packed in flexible tubes.

The most common toothpaste tubes are mainly made of plastics or aluminum plastic composite materials. The barrier layer of the plastic tube is EVOH, while the barrier layer of aluminum plastic composite tube is aluminum foil.

For the aluminum plastic composite toothpaste tube, the general structure is composed of heat seal layer, adhesive layer, barrier layer, adhesive layer and printing layer, from inside to outside. The compound strength tube can directly influence the mechanical property and barrier property of the aluminum plastic composite toothpaste tube. To be specific, if the compound strength of the composite toothpaste tube is insufficient, delamination may occur to the composite layers and as a result, the quality of the toothpaste within shelf life cannot be guaranteed. Therefore, it is necessary to test the compound strength of the aluminum plastic composite toothpaste tube before use.

This article provides a simplified test method of the compound strength of the toothpaste tube by measuring its peeling strength. The testing instrument for the peeling strength tests is Link Testing’s LTS-05 Auto Tensile Tester.

Figure 1. Toothpaste Tubes

The tests shall be performed according to the following procedures.

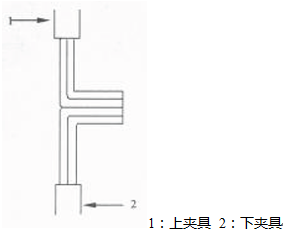

Figure 2. Mount Specimen

For more details about Link Testing’s LTS-05 Auto Tensile Tester, please visit www.linktesting.org

About Link Testing Instruments Co., Ltd:

Link Testing Instruments Co., Ltd is one leading supplier of packaging testing instruments, which is headquartered in Jinan, China