Source: Link Testing Instruments Co.,Ltd

People apply cosmetics to human skin or facial features through methods such as smearing, spraying, and sprinkling, in order to achieve the effects of cleaning, beautification, care, maintenance, and modification. According to the type, it can be divided into liquid, lotion, cream, powder, block, and oil. Liquid and emulsion cosmetics packaging are roughly divided into bottles, tubes, and bags. Bottled cosmetics are divided into two types of materials: plastic bottles and glass bottles. The bottle mouth is divided into rotary, push-pull and push-type. Among them, rotary bottle The mouth is often packed with screw caps, which need to be manually twisted and unscrewed before use. If the screw cap is too tight, it is not convenient for consumers to open it. If the screw cap is loose, the quality problem of bottle mouth leakage will occur.

How to solve the problems of easy opening and good sealing on the basis that the opening force required by the screw cap is within the acceptable range of the consumer for similar screw cap bottled cosmetics needs to be verified by effective monitoring methods. For the screw cap bottled cosmetics, this article uses the LTTT-20 torque meter independently developed by Link Testing Instruments Co Ltd. to test the torque value of the sample. The torque is used to determine whether the cosmetic is easy to open and not easy to leak, providing a technical reference for the cosmetics industry .

At present, China’s testing of the opening torque performance of bottle caps mainly refers to the method of “opening torque test” in GB/T 17876-2010 "Plastic Anti-theft Bottle Caps for Packaging Containers". This standard is suitable for use with polyolefin as the main raw material, through injection molding and heating. For bottle caps formed by pressing or other processes, the cap cannot be restored to its original packaging form after being sealed and then opened.

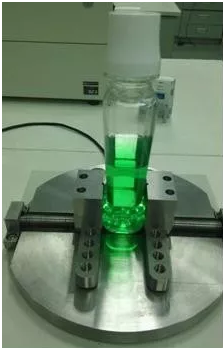

This test uses Link Testing LTTT-20 torque meter to test the torque when the bottle cap is opened.

Test sample and test process

Test sample: a certain brand of lotion packed in a plastic bottle with a plastic anti-theft bottle cap.

Experimental procedure:

(1) In a standard laboratory environment, place the adjusted cosmetic bottle sample on the instrument fixture and clamp it.

(2) Set the instrument mode to "Turn on torque" and click to start the test.

(3) Put your hand on the bottle cap and unscrew the bottle cap. At this time, the instrument automatically detects the opening torque value.

(4) Follow the above steps to test the remaining 2 samples in sequence.

Test results and analysis

The tested plastic bottle packaging cosmetic cap opening torque values are 0.405 Nm, 0.421 Nm, 0.417 Nm, respectively.

Bottled packaging products, nozzle packaging products, tube packaging products bottle cap locking, opening torque value is one of the process parameters offline or online key control of the production unit. This article uses the LTTT-20 torque meter to test the opening torque of the cosmetic plastic bottle cap. It has the advantages of high measurement accuracy and good stability, which can ensure that the bottled cosmetics are easy to open and have good airtightness.

Not only the manual torque tester LTTT-20, but also the automatic torque tester LTXGY-03S which could check torque performance automatically result accuracy be improved and the efficiency is higher and could test the childproof cap more easier.

For more details please visit our website: www.linktesting.org