Source: Link Testing Instruments Co.,Ltd.

Ultraviolet curing glue, means UV glue, refers to a type of adhesive that must be cured by ultraviolet radiation. It has the advantages of fast curing speed, simple curing equipment, energy saving, and convenient use. It can be used in handicrafts, glass products, circuit boards, optics, etc. Bonding of fibers and medical devices, coating and sealing of electronic devices, coating protective layers of optical discs, etc. For products that are bonded and packaged with UV glue, the moisture resistance of UV glue is an important factor affecting the amount of water vapor it contacts during use. For example, electronic products are more sensitive to water vapor. If the moisture resistance of UV glue used for packaging Poor, the water vapor in the environment will slowly penetrate into the package along the UV glue, affecting the service life of electronic products, especially for electronic products with extremely high moisture resistance of packaging materials, the water vapor of UV glue penetrates the level of the rate has become a crucial factor restricting the life of electronic products. Therefore, the moisture barrier properties of UV adhesives cannot be ignored.

Test methods and instruments

At present, there are three main test methods for water vapor transmission rate, namely cup method, electrolysis method, infrared method. The cup method is used in this test, and the standard is GB 1037 "Plastic Films and Sheets". Test Method for Water Vapor Permeability of Materials by Cup Method.

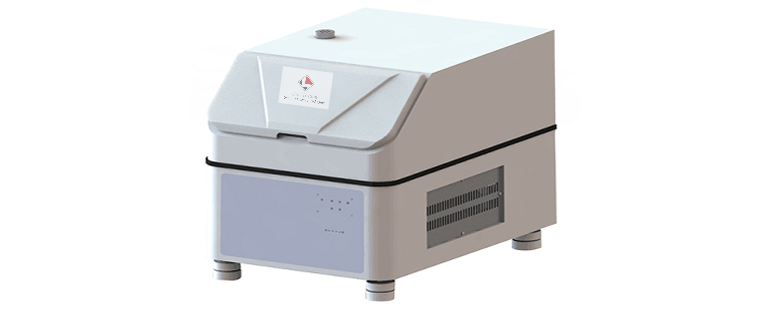

In this test, the LTWTC-203H water vapor transmission rate tester independently developed and produced by Link Testing Instruments Co., Ltd. was used to test the moisture resistance performance of the UV glue samples.

Test principle: The permeation process of gas molecules in solids follows the principle of dissolution and diffusion. According to this principle, the two sides of the sample are placed in different humidity environments to provide power for water vapor molecules to penetrate through the sample. When the water vapor transmission rate of the sample is tested by the cup method, the sample is sealed on the moisture permeable cup, and the humidity inside and outside the moisture permeable cup is controlled to form a certain humidity difference. The wet side penetrates through the sample to the low-humidity side, which causes the weight of the moisture permeable cup to change. By testing the change of the weight of the moisture permeable cup with time, the relevant parameters such as the water vapor transmission rate of the sample are obtained.

Test samples and test procedures

Test sample: UV glue produced by a company.

Sample process:

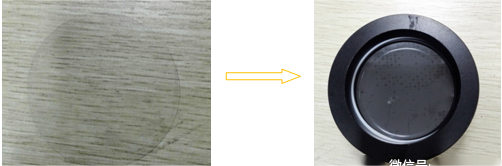

(1) Sample preparation: The liquid UV glue is made into a sheet sample with uniform thickness according to the method of use, and 3 samples with a diameter of 74mm are cut from the prepared sample by taking the sample.

picture

(2) Sample loading: Seal the 3 samples in three moisture-permeable cups containing a certain amount of distilled water, then put the moisture-permeable cups on the moisture-permeable cup holder inside the equipment, and close the test chamber door.

(3) Test: Set test parameters such as sample thickness, test temperature, humidity, test mode, etc., click the test option, the test starts, and the device automatically measures the weight change of the moisture permeable cup according to the set parameters.

(4) End of test: After the test, the device will automatically display the water vapor transmission rate of the tested sample.

Test Results and Analysis

The average water vapor transmission rate of the UV glue sample measured in this test is 561.439g/(m2·24h).

The water vapor transmission rate of the UV glue samples tested this time is relatively high, and the moisture resistance is poor. The LTWTC-203H water vapor transmission rate tester can obtain the average value of the test results of three samples in one test, with high test efficiency, accurate and reliable test results, and can truly reflect the moisture resistance and moisture resistance of the tested samples.

For more details please visit www.linktesting.org