Source: Link Testing Instruments Co.,Ltd.

According to YBB00382003-2015, the tear-off aluminum caps for liquid bottles are mainly tested as follows: mechanical properties of aluminum materials, opening force, sterilization resistance, suitability, coating firmness, etc. The following article analyzes the key points of the test of the mechanical properties and opening force of the aluminum material for the tear-off aluminum cover of the liquid bottle.

[Mechanical properties of aluminum parts]

1.1 Standard requirements:

It is stipulated in YBB00382003-2015 that the tensile strength of the aluminum material for tear-off aluminum caps for liquid bottles shall be 130N/mm2, and the elongation shall not be less than 3.0%.

1.2 Instrument: Link Testing Instruments Co.,Ltd. LTS-05 Automatic Tensile Tester

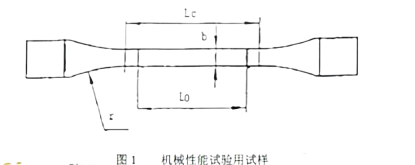

1.3 Sample: Take an appropriate amount of aluminum sheet of the same batch, use a tool with a width (b) of 12.5mm, an original gauge length (L0) of 50mm, a parallel length (Lc) of 75mm, and a transition arc radius (r) of at least 20mm Cut out the sample shown in Figure 1.

1.4 Operation:

(1) Clamp the sample taken on the LTS-05 fixture and clamp it.

(2) The test speed is 10mm/min±2mm/min.

(3) The measured tensile strength of the sample shall be 130N/mm2, and the elongation shall not be less than 3.0%.

[Opening force of tear-off aluminum cap for liquid bottle]

2.1 Standard requirements: YBB00382003-2015 stipulates that the tearing force should be 5.0-15N.

2.2 Instrument: Link Testing Instruments Co.,Ltd. LTS-05 Automatic Tensile Tester

2.3 Operation:

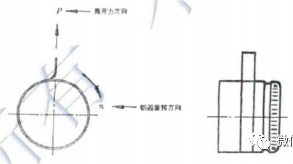

(2) The pulling force angle is 90 degrees, and the tearing force line speed is 10mm/s±2mm/s.

(3) If it breaks in the middle of the tearing process, it is an invalid experiment.

(4) According to the standard, the tearing force should be between 5.0N-15N.

For more details please visit www.linktesting.org