Source: Link Testing Instruments co.,ltd.

Abstract: Blister Packaging is the main stream of solid drug packaging. This article analyzes the testing requirements for blister packages, and introduces the corresponding testing methods for specific indexes basedon specific pharmaceutical package testing standards.

Key Words: blister, PTP, oxygen transmission rate, heat seal strength, impact resistance strength

Pharmaceutical blister packaging, also called PTP (press through packaging), is one of the main forms of pharmaceutical packaging. It’s suitable for the mechanized packaging for solid medicine with remarkable advantages. The main advantages of blister packaging are as follows: the medicine can be kept in stable and reliable condition; minor amount and serial packaging can be realized easily; the package is safe, hygienic, portable and convenient; it’s with great adaptability and long storage period. Meanwhile, blister packaging possesses many functions, including identification and counter forgery, etc. Now, blister packaging takes up about 30% of the global pharmaceutical packaging market with a trend of stable increase, and will be the main stream for the packaging of Western Medicine and its capsules and tablets, as well as for the packaging of Traditional Chinese Medicine, such as pills, powder and granule, etc.

1. Testing Requirements for Blister Packaging

The main packaging subject for blister package is the solid drug. The package should separate the

pharmaceuticals from the outside, and avoid the evaporation, release or leakage of the active ingredients inside them. The volatile pharmaceutical ingredients can dissolve inside the packaging material, and diffuse to the outside under the function of pressure differences. For example, the fragrant or volatile ingredients of the solid drug would evaporate and transmit through the materials. On the other hand, the package should guard against the air, moisture, foreign matter and microorganism from direct contact with pharmaceuticals inside. Oxygen, moisture, large amount of microorganism and foreign matters can be found in the air. When such ingredients enter into the packages, they would lead to oxidation, hydrolysis, degradation, pollution and fermentation of the pharmaceuticals.

Since the PTP aluminum foil, PVC sheets and the PVC/PVDC laminated sheets applied for the blister packages would contact the pharmaceuticals directly, the material testing should be especially noticed. The testing items include appearance, barrier property, tensile strength, impact resistance strength, thermal tensile ratio and other mechanical properties as well as hygiene indexes, etc., all of which have their respective testing methods and standards (or manufacturer’s standards). Hereinafter, the important testing items for blister packages will be introduced.

2. Barrier Property Testing

Barrier property testing is the key testing item for blister packages. Blister barrier property testing includes oxygen transmission rate testing and water vapor transmission rate testing. The testing of oxygen transmission rate for aluminum foil is not mentioned in the standards. However, owing to the fact that this index is in close relationship with the number of the pinholes, if this number can satisfy the requirements in the standards, the oxygen transmission rate can meet the requirement for usage. In actual application, both aluminum and PVC material have high barrier properties. Thus, instruments with high precision should be chosen when purchasing. The testing technologies for oxygen transmission rate and water vapor transmission rate have been popularized. The testing technology for the barrier property of whole blisters will be emphasized hereinafter.

The testing technology for whole package barrier property has become mature. Yet, owing to its small sizes, the whole blister package cannot be tested by the existing whole package testing fixtures. Meanwhile, the strength of aluminum foil is weaker than that of plastics; and thus, whole package barrier property testing technology has not been put to use in blister packages. In fact, owing to the evenness of the adhesives, thermal tensile ratios of the materials as well as the force of aluminum foil, the actual oxygen transmission rate and water vapor transmission rate are higher than the calculated values obtained from the data of film barrier property testing. We have tested some of the pharmaceuticals with blister packages, which are then compared with the actual permeability data of PVC sheets or PVC/PVDC laminated sheets from manufacturers. We have discovered that the barrier property data of the whole blister packages obtained from actual measurement may vary tens of times, though the barrier property data of packaging materials are similar.

We use specially designed fixture to prepare the blister specimen when testing the barrier property of the whole blister. Equal pressure method for oxygen transmission rate testing and sensor method for water vapor transmission rate testing are applied. During the testing process, the adjustment of the flow velocity should be especially taken care of, so as to avoid influences to the specimen status caused by the great gas quantity change and the corresponding dramatic pressure change inside the blister. The testing fixtures for blisters can also be applied in the testing for capsules or other small containers to enlarge the testing scope.

At the same time, the testing for volatile pharmaceutical ingredients may refer to the testing methods for organic gas permeability rate. Our country has drafted the world innovative organic gas transmission rate testing standards (including container testing), which is believed to provide effective testing methods for transmission of volatile pharmaceuticals.

3. Heat seal Strength Testing

Similar to other types of packages, sealing performance is an important index for the practicality of blister

packages, and heat seal strength is an important testing item for sealing performance. As to blister packages, both in the testing for aluminum foil and PVC sheet, or aluminum foil and PVC/PVDC laminated sheet, heat seal strength testing is no exception.

The testing method for heat seal strength is as follows: choose suitable heat seal parameters according to the specific testing standards; heat seal a piece of PVC sheet or a piece of PVC/PVDC laminated sheet (to stack the adhesive side of the aluminum layer with the PVC sheet) at the size of 100mm×100mm with a heat sealer; then, cut the specimen with a width of 15mm, and choose three pieces from the middle part to carry out 180°peeling with a tensile tester (peeling speed as per the specific standards); and the maximum work done for peeling is the heat seal strength.

4. Thermal Tensile Ratio Testing

Thermal tensile ratio is the important testing item for PVC sheet or PVC/PVDC laminated sheet; it’s defined as the size changes after enduring a certain temperature within a certain period of time, and is the ratio of the spot distance variation and the initial spot distance in percentage. The test should be carried out according to YBB00292004, Test Method for Thermal Tensile Ratio.

Cut two square pieces, with each side of 120mm±1mm, from the sheet. Cut through the central position; and carve two vertical lines, namely AB (lengthwise) and CD (crosswise) with a spot distance of 100mm±1mm; then, carve at the top of those two lines; measure the lengths of AB and CD precisely and calculate the arithmetic mean value. Put the square pieces on the glass or metal panels, and not to affect the free deformation of them. Place the square pieces horizontally into a heater at a temperature of 100℃±1℃ for 10 minutes, and then take out to cool down to the room temperature, measure the lengths of AB and CD precisely; and calculate the arithmetic mean values. The thermal tensile ratio is required to be within ±6% by the standards.

5. Impact Resistance Strength Testing

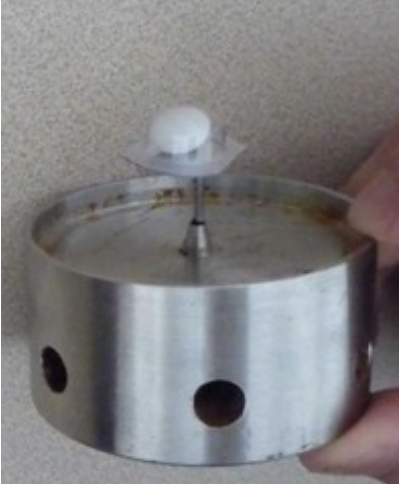

Press forming is an important procedure in the manufacturing process of blister packages. Therefore, the testing for the impact resistance strength of PVC sheet or PVC/PVDC laminated sheet is of great significance. Falling ball impact tester should be used for the testing.

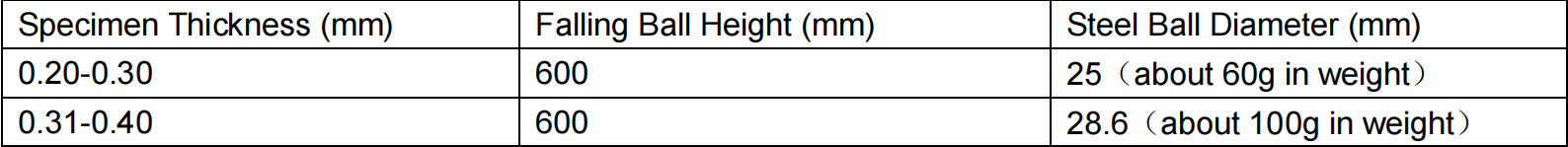

Take out a certain amount of products, and cut five specimens with a length of 150mm and a width of 50mm. Place the specimens in a 23±2℃ and 50±5%RH environment for 4 hours, and carry out tests in the same environment. Fix the specimens onto the falling ball impact tester with a distance of 100mm each. As to PVC/PVDC laminated sheets, the PVDC layer should be upwards. Select the steel ball and falling ball height as per the following chart. The steel ball falls freely along the center of the gaps. The damage should be no more than two pieces both in lengthwise and crosswise.

6. Conclusions

Nowadays, the construction for blister packaging standards has taken shape in our country; but it is far behind the pharmaceutical packaging material standards and regulations of the developed countries. The main problems lie in the low testing index requirements, delayed standard update and laggard testing methods, etc. The requirement of the standard is a main means to guide the development of testing technology and the promotion of packaging quality. Therefore, the standards and regulations for pharmaceutical blister package should be perfected and timely updated, so as to promote sound development of the pharmaceutical blister packaging market.

For more details please visit www.linktesting.org