Source: Link Testing Instruments Co.,Ltd.

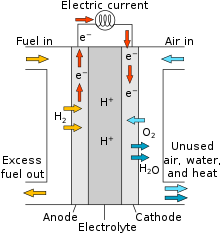

Proton Exchange Membrane Fuel Cell (PEMFC) is a fuel cell that uses an ion-conducting polymer membrane as an electrolyte, so it is also called polymer electrolyte fuel cell (PEFC), homogeneous polymer fuel cell (SPFC) or solid polymer electrolyte fuel cell (SPEFC). PEMFC has a high energy conversion rate, which can usually reach 90%, much higher than the energy conversion efficiency of traditional internal combustion engines. Due to its high efficiency and environmental protection characteristics, PEMFC has broad application prospects in new energy vehicles, fixed power stations and other fields. However, its manufacturing cost and durability issues are still the main factors restricting its large-scale commercialization. In the future, with the continuous advancement of technology and the reduction of costs, PEMFC is expected to become an important clean energy solution.

As the core component of PEMFC products, proton exchange membrane not only has a barrier effect, but also has the function of conducting protons. Its performance is directly related to the overall performance and efficiency of the fuel cell. Therefore, R&D companies and units have paid special attention to its relevant performance indicators.

At present, China has issued a number of industry standards for the quality inspection of key components of "proton exchange membrane fuel cell" products, such as "GBT 20042.3-2022 Proton Exchange Membrane Fuel Cell Part 3: Proton Exchange Membrane Test Method", "GBT 20042.7-2014 Proton Exchange Membrane Fuel Cell Part 7: Carbon Paper Property Test Method", "GB/T 20042.5-2009 Proton Exchange Membrane Fuel Cell Part 5: Membrane Electrode Test Method", etc.

This article will mainly focus on the core component "proton exchange membrane", taking the GBT 20042.3-2022 standard as an example, to provide industry customers with corresponding testing services and instrument solutions.

As one of the core components of PEMFC, the proton exchange membrane can separate the cathode and anode, preventing the fuel (hydrogen) and the oxidant (oxygen) from mixing directly to produce a chemical reaction. This effect can be evaluated by gas permeability. The higher the gas permeability, the worse the gas barrier performance of the membrane. The more hydrogen and oxygen come into contact, the lower the potential difference between the two electrodes of the battery, and the lower the open circuit voltage of the battery. Therefore, the gas permeability index of the proton exchange membrane material is very important and is one of the performances that companies need to focus on monitoring.

The GTC-203H differential pressure gas permeability tester independently developed and produced by Link Testing is a gas permeability tester professionally used for thin film samples. The instrument adopts the differential pressure test principle and complies with and meets the test requirements for the "gas permeability" and "gas permeability coefficient" indicators of proton exchange membranes in the standard GB/T 20042.3-2022 "Proton Exchange Membrane Fuel Cell Part 3: Test Method for Proton Exchange Membrane". It can be professionally used to detect the gas permeability performance of proton exchange membranes. Through personalized customization, it can meet the needs of customers to test the permeability of flammable and explosive gases such as hydrogen on materials.

2. Tensile Strength & Peel Strength

The mechanical strength of the proton exchange membrane is directly related to the material's ability to withstand mechanical damage, which in turn affects its mechanical stability and the life of the fuel cell stack. Standard GB/T 20042.3-2022 has clear requirements for the testing of "tensile strength", "tensile strain at break", "elastic modulus" and "180° peel strength".

The LTS-05 intelligent electronic tensile testing machine developed and produced by Link Testing completed the test. This instrument is an electronic tensile testing machine that is professionally used to test the tensile properties and other mechanical properties of various soft materials. It is equipped with a high-precision force sensor better than level 0.5. One testing machine integrates professional and independent testing programs such as stretching, peeling, tearing, heat sealing, fixed elongation and tensile strength, and downward pressure, providing users with a variety of test items to choose from, which can meet a variety of testing needs. In combination with standard test requirements, the LTS-05 tensile testing machine can complete the tensile height, breaking elongation, and 180° peel strength tests of proton exchange membranes. At the same time, it is equipped with a professional puncture force test fixture to test the puncture resistance of membrane materials. One machine has multiple uses and is extremely cost-effective.

3. Thickness detection

The thickness of the proton exchange membrane is closely related to the safety and performance of the fuel cell. This is because the proton conduction resistance of the proton exchange membrane is one of the main components of the output pressure drop of the fuel cell. A large thickness means a large conduction resistance and low performance, while a small thickness means it is easy to be crushed and pierced. On the other hand, the reverse diffusion of bound water in the proton exchange membrane from the cathode side to the anode side is driven by the water content gradient between the two sides. A small thickness means a large water content gradient and strong reverse diffusion, which allows more bound water to migrate and increase the current density in the active area. It can be seen that it is particularly important for companies to determine and monitor the thickness parameters of the proton exchange membrane.

For the thickness uniformity test of proton exchange membrane, it is recommended to use LTCHY-HS thickness gauge for measurement. LTCHY-HS is a high-precision, high-repeatability mechanical contact precision thickness gauge, which is professionally suitable for the precise thickness measurement of various materials within the measuring range, such as film, sheet, paper, corrugated cardboard, textile materials, non-woven fabrics, solid insulation materials, etc.

During the research and development process, researchers will improve the performance of proton exchange membranes by optimizing material selection, improving preparation processes, adjusting membrane structures, etc. In addition to the above main performance indicators, the water conductivity, swelling degree, electroosmotic coefficient, etc. of proton exchange membranes are also the focus of research and development companies and units.

For more details please visit www.linktesting.org