Source: Link Testing Instruments Co.,Ltd.

Shampoo is a common daily chemical product, mainly used for daily care of the head skin and hair. The commonly used packaging forms include bottled and bagged. Bag shampoo is divided into large and small volumes. Most of the small-volume (such as 5 mL) shampoo packaging bags are disposable. While this type of bagged shampoo brings convenience to consumers, the problem of the bag opening being difficult to tear open is a common problem that troubles its convenience of use. In order to improve the tearing performance of the bag opening, a certain shape of easy-tear opening is usually preset at the shampoo bag opening. However, due to the large tear resistance of the packaging material itself or the insufficient strength of the interlayer composite, it is easy to have a tear opening that is difficult to tear open or the outer layer is pulled off and the inner layer is stretched, which brings inconvenience to use. In addition, considering the use environment of shampoo, the surface of the packaging bag will inevitably be wet, which increases the difficulty of tearing the packaging bag. Therefore, by testing and controlling the tearing performance of the packaging material, improving the tearability of the shampoo packaging bag is an effective measure to improve consumers' satisfaction with the product.

Testing Basis and Test Machine

The test methods for the tearing performance of soft plastic packaging include right-angle tearing method, trouser-shaped tearing method, and Elmendorf method. The samples tested in this article adopt the incision form of easy tearing. According to the shape of the easy tearing mouth and the angle of force applied when being torn, this test adopts the trouser-shaped tearing method to test the samples. The test is based on the standard GB/T 16578.1-2008 "Determination of tear resistance of plastic films and sheets Part 1: Trouser-shaped tearing method".

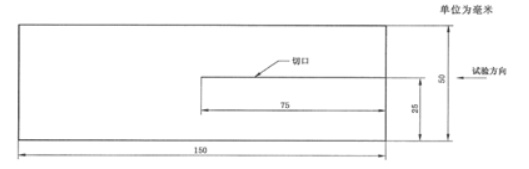

Test principle: The trouser-shaped tearing method refers to the shape of the tested sample being similar to "trousers" (see Figure). During the test, the two "trouser legs" of the sample are clamped in the upper and lower clamps of the equipment respectively. When the upper clamp of the equipment moves upward, it will pull one "trouser leg" of the sample to tear the sample along the long axis. The force value and displacement changes during the tearing process are recorded in real time by the force sensor and displacement sensor configured by the equipment to form a test curve. The average force value tested in the test is the tearing force of the sample, and the tearing strength of the sample is calculated based on this.

Test sample and test process

Test sample: This test uses a certain brand of aluminum-plated composite film for shampoo packaging as the test sample. Test process:

Test results and analysis

The longitudinal tear strength of the sample tested in this test is 11.465 kN/m, and the transverse tear strength is 8.027 kN/m.

For more details please visit www.linktesting.org