In modern agriculture, the selecting, transportation and sowing of seeds are all realized by automatic mechanization, which also makes a great contribution to the increase of output of grains and income of farmers. The coefficient of friction of the seeds against agricultural machinery may influence the working efficiency greatly. The coefficient of friction is one main factor that shall be considered when selecting surface materials of agricultural machinery and determining related parameters.

The raw seeds are usually mixed with broken pieces of seeds, weed seeds, crushed straws and sand grains, etc., which carry a large amount of bacteria. Those foreign matters are liable to absorb moisture and thus speed up the deterioration of the seeds. The cleaning and selecting of seeds is a process during which the seeds are cleaned and separated for different levels of quality.

Seed selecting machine is equipped with feeding hopper, cloth tape and two roll shafts. The cloth tape is installed between the upper and lower roll shaft, at a certain angle to the ground and rolling at a certain speed. When the material of cloth tape and the angle are fixed, the seeds are liable to slide down because of the lower coefficient of friction of the seeds against cloth tape. While the sand grains, grass and straws will be carried by the cloth tape because of the higher coefficient of friction, so the seeds will be separated from other foreign matters successfully.

After cleaning and separating, the seeds will be carried to next process by the conveyor belt. The coefficient of friction of the surface material of conveyor belt against the seeds should be sufficient otherwise the seeds may slip off the conveyor belt during transportation. Seed metering device, as the core part of seed sowing machine, decides the precision of seed sowing. During the seed sowing process, the seeds will contact the seed metering device directly and the coefficient of friction of the device against seeds may influence the smoothness of seed sowing. Therefore the coefficient of friction is one main factor that should be considered when selecting raw materials for seed metering device in the research and development of seed sowing machine.

Test Method of Coefficient of Friction of Seeds

link testing’s LTCOF-05A Coefficient of Friction Tester is a professional tester that can be used to test the static coefficient of friction and kinetic coefficient of friction of plastic films, sheeting, rubber, paper, cardboard, woven bag, fabrics, metal compound belt used for communication cable, conveyor belt, wood, coating, brake pad, windshield wiper, shoe material, tyre and many other materials. This instrument conforms to multiple Chinese and international standards including ISO 8295, ASTM D1894, TAPPI T816 and GB 10006.

The test specimen is placed on the test plane with testing surface facing upward. The test specimen shall be paralleled to the longitudinal direction of the test plane. The testing surface of the other specimen shall face downward and fixed on the lower surface of the sled using double-faced adhesive tape. Then place the sled on the center of the test plane so that the testing surfaces will contact directly with each other. The specimens remain still for 15 seconds. Then the specimens move in the opposite direction. Static and kinetic coefficient of friction will be calculated automatically.

Because the shape of the seed is irregular, in the test the seeds are scattered uniformly on the surface of rigid cardboard with adhesives. The cardboard is fixed on the test plane. The material that contacts the seeds is fixed in the sled. At least 3 times of tests need to be performed and the final result will be the average value of all the test results of those tests.

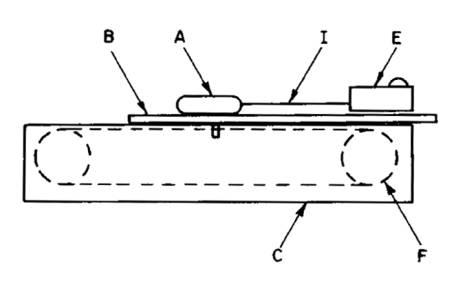

Figure 1. Schematic Diagram of Working Principle of LTCOF-05A Coefficient of Friction Tester

A.Sled B.Test Plane C.Base E.Load Cell F.Constant Speed Driving Mechanism I.Nylon Filament

3. Related Documents

In Measurement of physical and mechanical parameters for the small seed seeding, link testing’s LTCOF-05A is used as the testing instrument to test the coefficient of friction of small seeds such as millet, alfalfa, rape and sesame. The friction pairs are steel, aluminum, plastics and wood. The static coefficient of friction is 0.522, 0.767, 0.588 and 0.803, respectively. The kinetic coefficient of friction is 0.499, 0.919, 0.557 and 0.873, respectively.

In Experimental study on friction characteristics of broomcorn millet with different moisture content, link testing’s LTCOF-05A is used as the testing instrument to test the coefficient of friction of broomcorn millet with different moisture content. For example, at the same moisture content 17.6%, the static coefficient of friction of broom millet against steel plate, iron plate and acrylic board is 0.227, 0.246 and 0.236, respectively. The kinetic coefficient of friction is 0.219, 0.234 and 0.224, respectively (All test data is from Experimental study on friction characteristics of broomcorn millet with different moisture content) .

Conclusion

link testing’s COF testers are professionally designed for determination of coefficient of friction of materials in laboratory, which are featured with high efficiency, accuracy and repeatability.

link testing Instruments Co., Ltd, as one global leader in R&D and manufacturing of packaging testing instruments, is dedicated to providing global customers with professional high-end testing instrument and testing service as well as tons of testing data for reference.

Please visit www.linktesting.org to get more information for link testing and its testing instrument and services.